- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: JIANGSU,CHINA

- Brand Name: NEWLINE MACHINERY

- Model Number: NLM18-18-6H

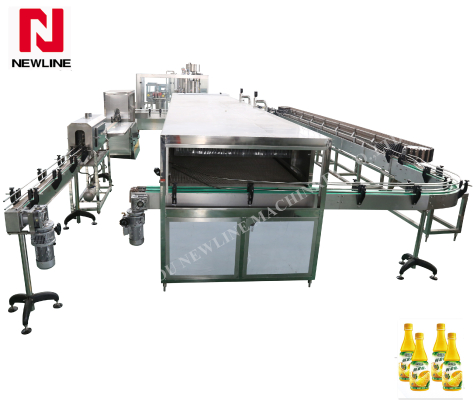

Automatic small scale juice bottling plant

1). The raw water will be purified and sterilized after passing through the water treatment system, and will be stored in the purified water storage tank

2). The juice will be prepared by the juice preparation system, the prepared juice is stored in the insulation tank (for heat preservation) temporarily

3). Automatic heat resistance PET bottle blow molding machine is connected with the water filling machine by the Air conveyor

4). Prepared juice will be pumped into the juice filling machine; At the same time, empty bottles pass through the rinsing, filling and capping 3-in-1 monoblock, the bottles will be rinsed, filled and capped.

5). Bottled water goes out from the water filling machine and will be transferred to the bottle over-turn sterilizing machine, the cap and the bottle mouth will be sterilized after passing through the sterilizing machine, then the bottles will be transferred to the bottle cooling machine

6). The bottles are getting dried after passing through the blowing dryer, and the dried bottle will go to the labeling machine and PE film shrink wrapping machine

7). The packed bottle water will come out from the PE film shrink wrapping machine.

Advantages of our juice filling machine

1). Full filling to avoid the liquid level from sinking after the bottle cooling down, and to decrease the dissolved oxygen to the utmost extent.

2). Reasonable structured storage hopper and material supply system make the material in constant flow speed, constant pressure without frothing. Usually high position tank is adopted.

3). The storage hopper has the characteristic of gas discharge, full sealing and temperature detecting. In moderate and high speed production line, the material distributor replaces the big liquid tank to realize the complete CIP.

4). Sanitary filling head system is of umbrella structure, high filling speed.

5). Perfect filling temperature control system.

6). Reflux tank system has the function of supplying the material automatically.

7). Perfect CIP system.

- Place of Origin: JIANGSU,CHINA

- Brand Name: NEWLINE MACHINERY

- Model Number: NLM18-18-6H